Custom process

We support exclusive custom design services

Factory Work Flow

A complete set of factory operation processes

Please contact us by phone or email and tell our sales staff the content you want to print. We will analyze your needs, give you our suggestions, and make a quotation and construction period. After confirming the production intention, we will immediately enter the implementation stage.

We optimize the information provided by customers, make full preparations for pre-press, produce according to customer needs, and finally give satisfactory manuscripts to customers for confirmation.

After the electronic manuscript is confirmed, we will make a proof or digital manuscript according to your needs and submit it to you for review. After the manuscript is confirmed, CTP plate output will be carried out and the printing process will be arranged.

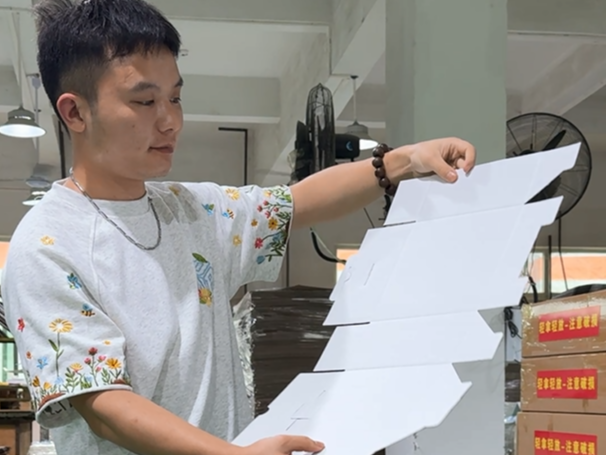

After receiving the production arrangement, the professional printing team will carry out paper cutting, ink mixing, color management according to your product requirements, and finally print excellent printed products.

After printing is completed, the next step of processing will be carried out. Post-processing can improve the grade and practical functions of the product, including oiling, UV, lamination, hot stamping, embossing, embossing, etc., as well as folding, at least gluing, hardcover and other processing techniques, as well as a series of processes including die-cutting, special-shaped, pasting and mounting, gluing boxes, etc.

After the printing post-processing is completed, our inspectors and quality personnel will check again whether the finished products meet the quality requirements according to your requirements, and arrange packaging and warehousing after confirming that they are correct.

Manage samples according to the customer’s printing color and printing process to provide accurate comparison for re-production.

Connecting with the business departments for after-sales processing and responding quickly, through the combination of standardized processes and flexible solutions, the factory’s after-sales processing aims to quickly solve problems, reduce customer losses, and enhance cooperative trust through continuous improvement, assisting the business in helping customers to operate stably in the long term.

Inquiry

We provide flexible customization options, you can integrate brand logos, product information and other elements to enhance the unique brand image and appeal of your products. Tell us your needs!

Drawing design · Sample-based design · Independent development design · Printing logo and label · Size customization

Design confirmation

Custom Paper Box Confirm: Type confirmation, Material select, Surface & label, Insert confirmation, Size of your custom paper box, The quantity you need.

Custom Paper Bag Confirm: Material select, Bag Style, Printing Art Select, Surface & logo, Handle confirmation, Size of your custom paper bag, The quantity you need.

Receive the design draft and proofread the first draft, output the proofreading and ask the customer for modification opinions, modify according to the customer’s requirements, output the proofreading again and confirm, the customer confirms the final draft and signs

Sample confirmation

After the electronic manuscript is confirmed, we will make a proof or digital manuscript according to the needs and submit it to the customer for review. After the manuscript is confirmed, CTP plate output will be carried out, and the printing process, post-press processing, and inspection will be arranged. After the inspection is completed, it will be connected to the business department.

The sample will be handed over to the business department, and the business department will check with the customer (video or physical inspection), make improvements, and finally confirm the sample.